Life in a seasonal fashion business, and especially in the toy industry, is always an exercise in navigating stormy seas and facing highly volatile weather patterns that change each and every year. Despite the soul crushing nature of the coronavirus pandemic, much of the toy industry spent 2020 turning lemons into lemonade. Toy industry sales shot up 16% for the year as work from home parents and home schooled kids had to try to coexist 24/7 in the same confined space. Many toy categories exploded as desperate parents moved through several stages of grief from: “keep them occupied” to “shut them up” and finally to a more enlightened “shut them up and keep them occupied with something that might be good for them.” Home improvement and “nest feathering” also skyrocketed as seen by sales gains at Home Depot, and in big inflatable pools and backyard trampolines that will probably never be used again.

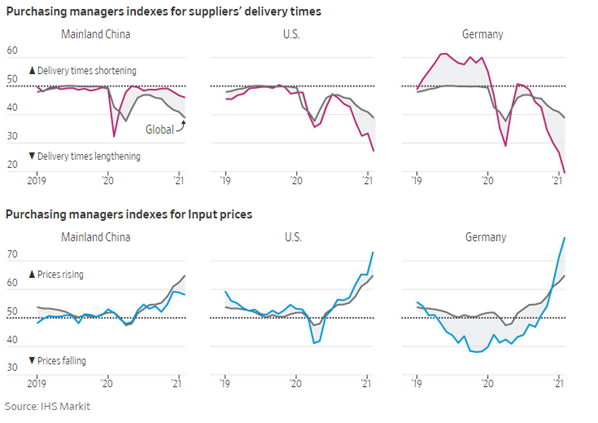

All of this spending has caused a shipping glut. The need to ship so many goods from Asia to the U.S. and Europe for an extended period of time has caused ubiquitous delays. There is a shortage of containers, shortage of space on ships, shortage of ship port parking, shortage of unloading equipment, shortage of dock workers, shortage of trucks to take the goods across the country to a Wal-Mart near you and a shortage of drivers to drive the trucks, if there were enough trucks to drive.

The global freight shortage has second and third degree effects as well. It isn’t just finished goods that are bogged down by slow travels. Manufacturing inputs face shipping shortages in turn. Materials need to find their way to factories which means that everything from semiconductors to paints and plasticizers to widgets of every description need to be driven, flown, or floated to the factory door. Additionally, the Texas freeze temporarily shut down the numerous petrochemical mega-plants located in the region resulting in shortages of various kinds of plastic resins as well. Recent decisions by both OPEC+ and the Biden Administration have also resulted in the prices of transportation fuels like gasoline and diesel (not to mention jet and boat fuel) spiking up as well.

One thing we know about shortages is that they drive up prices as companies decide they will just pay more to have their products made and moved. This ends up being one big upward inflationary spiral. The potentially good news is that this was all put in motion by the pandemic and the pandemic may be in the early stages of coming to an end. That may depend on a race between vaccine and variants. Over the last few weeks vaccination rates in the U.S. have much improved. Also, most vaccines being used here have been shown to be effective against B117, the most widespread of the variants. However, there are more variants out there and Covid-19 is mutating into new variants all the time. A quick glance at the horizon shows potential trouble brewing. Experience has shown us that what happens in Europe happens here a few weeks later and Europe is currently in the midst of a variant onslaught.

We may outrace a coming variant storm through ramped up vaccinations or we may just somehow dodge it. If that is the case there could be other potential problems. Better problems to be sure but, problems nonetheless. Once the pandemic begins to die down many observers hypothesize that the supply chain will begin to catch up and normalize during the second half of the year. That sounds reasonable and I hope that’s the way it works out. On the other hand we’ve pumped an awfully lot of stimulus into the economy and while a lot of people are suffering, a lot of other people’s bank accounts are fuller than they’ve ever been. As we start to put COVID-19 behind us, I expect a BURST of euphoria and pent-up demand. Like most observers I expect demand to be focused on experiences like bars, restaurants, concerts, travel, theme parks and big nights out. That said, Christmas comes every year and so does holiday spending. I can certainly see a big spending spill into holiday gifts. I would look for the much talked about consumer savings to be spent and more than spent by the end of the year. That would be a high class problem. A much better problem than another round of “lockdowns” – but it would leave supply chain executives looking like the comedy scene in an old western movie – tapdancing bullets.

…..Sigh…..worst case scenario – the U.S. continues to do pretty well in vaccinating the public but come springtime, when the good weather comes, people are just done with Covid. No more masks, no more distancing. The bars and restaurants and beaches are full. So are the airports, the cities and hotels – and “suddenly” we get slammed with a Covid variant storm. I surely hope that’s not what happens but if you ask me quietly, that’s what I’m afraid of. You can already see it starting to set up.

Closer to home and on a cheerier note – record setting 2020 toy sales have continued to drive strong toy industry hiring. At Toyjobs we are rocking around the clock! I see that continuing unless we see a strong and prolonged bout in bad pandemic news. Every single person that I’ve spoken to really missed the New York Toy Fair. Few missed the whole annual odyssey from Hong Kong to Nuremburg to New York….but New York, they missed. Hopefully, everything begins to normalize and we can all gather together at various venues in October. That said, in the toy business never expect completely smooth sailing.

Fingers crossed,

Tom Keoughan

Leave A Comment